articles/Printers/cardsharps-page4

Card Sharps - part 4 of 1 2 3 4 5 6 7

by Mike McNamee Published 01/02/2012

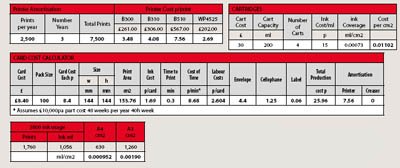

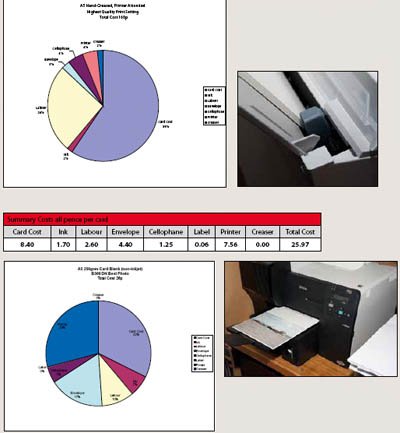

Various tables extracted from the spreadsheet cost calculator we developed. We were also to do a few 'what if' calculations. Ink costs are difficult to estimate. On the left is the usage over a two-year period for a 3800 printer. 1,760 prints used 1,056ml of ink. The upper and lower bound estimates are made for all prints being A4 and all prints being A3 - the reality must lie in between. Above, the cost summary takes the actual inked area and the ink cost is 1.69p per card, even with a 100% error on ink usage this would only affect the total production cost by 6.5%. The pie charts indicate which area to concentrate your efforts on when tuning your costs.

The highest cost we estimated was for using a fine art paper, hand creasing it, attending the printer for a slow printing speed and costing in the time. Note in the pie chart that the cost of the fine art paper dominates the cost, followed by the labour cost.

A very heavy, fine art paper can be loaded only 10 sheets at a time before you reach the 9mm limit of the WP 4245.

Labour costs are sensitive to a need to attend the printer.

The lowest cost estimate we achieved was 26 pence for an A5 card, using an Epson B510, a 256gsm prepared card blank, including envelope, cellophane and label. It involved a 22 second print time. At this speed and cardblank cost, the printer amortisation starts to loom large in the pie chart.

Please Note:

There is more than one page for this Article.

You are currently on page 4

- Card Sharps page 1

- Card Sharps page 2

- Card Sharps page 3

- Card Sharps page 4

- Card Sharps page 5

- Card Sharps page 6

- Card Sharps page 7

1st Published 01/02/2012

last update 09/12/2022 14:52:17

More Printers Articles

There are 0 days to get ready for The Society of Photographers Convention and Trade Show at The Novotel London West, Hammersmith ...

which starts on Wednesday 15th January 2025