articles/Paper/rollup-page3

Roll Up Roll Up Roll Up - part 3 of 1 2 3 4

by Mike McNamee Published 01/06/2009

A simple elastic band holds the rolled assembly together.

This then is the back drop to the tip we are presenting. The method is simple, you roll up the unprinted paper (or the print) in a short length of canvas inkjet media which is on a 3-inch core, making sure that the curl is being reversed. The canvas gently forces the delicate surface around the core, holds it tightly and does not scuff it or crinkle it. If the paper is to be left wrapped for more than a few minutes we slipped an elastic band around it.

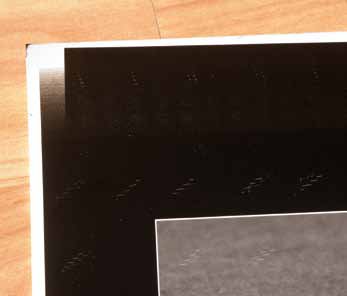

The effect of paper shifting as it exits the printer, scuffing damage and a displaced, ghostimage to the side of the true position.

How well does it work?

The image shows a sample of flat-stored, sheet, baryta paper standing on a flat surface. It has assumed a complicated curl, up at the edges, generally curled upwards across the short edge but with a hump in the middle. We measured the residual curl with a vernier depth gauge, flattened the sheet with the method described and then measured again. We tested 'wrapped up' time intervals of 1, 4, and 10 minutes. Most of the benefit came after one minute. After the 'uncurling' the sheet remained at the better level of flatness for at least three hours (when we put it away again!). The initial level of curling (a maximum of 10.5mm) was sufficient for these sheets to have suffered from both head strikes and skewing when they were used in a Paper Chase test (in an Epson 3800).

Please Note:

There is more than one page for this Article.

You are currently on page 3

- Roll Up Roll Up Roll Up page 1

- Roll Up Roll Up Roll Up page 2

- Roll Up Roll Up Roll Up page 3

- Roll Up Roll Up Roll Up page 4

1st Published 01/06/2009

last update 09/12/2022 14:58:38

More Paper Articles

There are 0 days to get ready for The Society of Photographers Convention and Trade Show at The Novotel London West, Hammersmith ...

which starts on Wednesday 15th January 2025